CURRENT ANALYSIS

Introduction

MTM’s senior consultant has 25 years experience in the pulp industry spanning maintenance responsibility, production management and has conducted independent consulting both within New Zealand and Internationally.

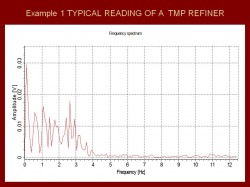

Current analysis was developed primarily to investigate the reason for load swings on thermal mechanical refiners in the pulp industry.

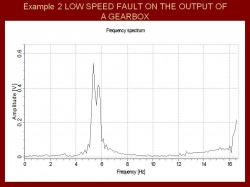

It soon became obvious that current analysis was a very useful tool for predictive maintenance and was extremely successful in picking up faults in low speed machinery.

Current analysis was developed primarily to investigate the reason for load swings on thermal mechanical refiners in the pulp industry.

It soon became obvious that current analysis was a very useful tool for predictive maintenance and was extremely successful in picking up faults in low speed machinery.

Background

-Power load swing has often been seen to be inherent within the refining process. MTM’s senior consultant has spent several years studying the characteristics of these load swings and their causes.

-Advances in technology, tools and analytical techniques combined with industry experience has provided insights into the relationship between “machinery faults” and the resultant load swing experienced.

-The issues causing these load swings can be translated directly into business impacts in terms of operating costs and product quality (revenue)

-“Machinery faults” may be anything from uneven wear on feed screws, faulty plates, to worn bearings in gearboxes.

-MTM analysis is most effective at identifying problems in low speed machinery. Other techniques such as vibration analysis have a solid history of identifying faults in higher frequency equipment making these complimentary rather than competing techniques.

-Advances in technology, tools and analytical techniques combined with industry experience has provided insights into the relationship between “machinery faults” and the resultant load swing experienced.

-The issues causing these load swings can be translated directly into business impacts in terms of operating costs and product quality (revenue)

-“Machinery faults” may be anything from uneven wear on feed screws, faulty plates, to worn bearings in gearboxes.

-MTM analysis is most effective at identifying problems in low speed machinery. Other techniques such as vibration analysis have a solid history of identifying faults in higher frequency equipment making these complimentary rather than competing techniques.

Benefits TMP and MDF

Load swings have been identified to cause direct increases in plant operating costs in terms of the following specific areas;

-Power consumption: (typically $250K-$300K pa)

-Reduced plate life:

-Reduced bearing life:

-Reduced guide valve life:

-Reduced blow valve life:

-Reduced packing life:

-And in some cases dryer energy

Additionally load swing can impact on revenue in terms of

-Reduced product quality (due to shorter fibre length etc)

-reduced productivity (due to inability to refine greater quantity for same power consumption)

-Power consumption: (typically $250K-$300K pa)

-Reduced plate life:

-Reduced bearing life:

-Reduced guide valve life:

-Reduced blow valve life:

-Reduced packing life:

-And in some cases dryer energy

Additionally load swing can impact on revenue in terms of

-Reduced product quality (due to shorter fibre length etc)

-reduced productivity (due to inability to refine greater quantity for same power consumption)

MTM Services

A)MTM can provide the information and a data analysing package with a step by step guide to allow you to perform your own current analysis at very little cost.

B)No expensive training required. Our package will explain in simple terms how to perform your own analysis.

C)No expensive equipment required.

D)Our current analysis club will offer continued support and free updates to enable clients to provide continuous improvement for their plant.

B)No expensive training required. Our package will explain in simple terms how to perform your own analysis.

C)No expensive equipment required.

D)Our current analysis club will offer continued support and free updates to enable clients to provide continuous improvement for their plant.

Copyright.All rights reserved.All trademarks are the property of their respective owners.